|

Hebei Land Wire Mesh Prdoucts Co.,Ltd.

|

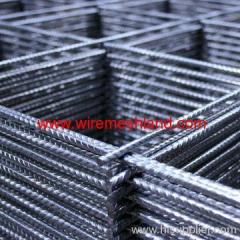

galvanized welded mesh

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Galvanized welded mesh adopts superior zinc-coated wire as raw material and formed by automatic digital controlled we

Galvanized welded mesh adopts superior zinc-coated wire as raw material and formed by automatic digital controlled welding equipments. The finished product is level and flat in surface and strong in structure. Galvanized welded mesh offers superior corrosion resistance compared to standard carbon steel welded wire mesh without the expense of stainless steel. GAW (galvanized after welded/ woven) and GBW (galvanized before welded/ woven) are common terms in the welded mesh industry. It''''s widely used in industry, agriculture, transportation and mining for all such purposes as poultry houses, egg baskets, runway enclosures, draining rack, fruit drying screen and fence.

Galvanized Welded Mesh Materials:

The main materials of galvanized welded mesh are low carbon steel wire and stainless steel wire.

The main materials of galvanized welded mesh are low carbon steel wire and stainless steel wire.

Galvanized Welded Mesh Assortments:

Hot dipped galvanized before welding

Hot dipped galvanized after welding

Electro galvanized before welding

Electro galvanized after welding

Hot dipped galvanized before welding

Hot dipped galvanized after welding

Electro galvanized before welding

Electro galvanized after welding

Galvanized Welded Mesh Surface treatment:

There are various methods of galvanizing. Two of the most common ways are electro galvanized (prior to weaving / welding) and hot dipped galvanized(post weaving / welding).

There are various methods of galvanizing. Two of the most common ways are electro galvanized (prior to weaving / welding) and hot dipped galvanized(post weaving / welding).

Galvanized Welded Mesh Features:

Resistance to rust and corrosion

Uniform mesh and smooth surface

Easy handling, cutting and shearing

Available in roll or panel in a variety of wire diameters, meshes and heights Great versatility and multipurpose

Resistance to rust and corrosion

Uniform mesh and smooth surface

Easy handling, cutting and shearing

Available in roll or panel in a variety of wire diameters, meshes and heights Great versatility and multipurpose

Galvanized Welded Mesh Application:

* Draining rack

* Fruit drying screen

* Utilized as guards in buildings and factories

* Animal enclosure in agriculture

* Used in horticulture industry as tree guards and plant protection

* Wire containers, baskets and grills, such as egg baskets

* Suitable for making partitions and machine protection fences

* It can be made into various animal cages or fences for breeding animal with its excellent anti-corrosion property. The zinc coating offers a decorative outlook

* Used in mine sieving industries as sieving screen

* Draining rack

* Fruit drying screen

* Utilized as guards in buildings and factories

* Animal enclosure in agriculture

* Used in horticulture industry as tree guards and plant protection

* Wire containers, baskets and grills, such as egg baskets

* Suitable for making partitions and machine protection fences

* It can be made into various animal cages or fences for breeding animal with its excellent anti-corrosion property. The zinc coating offers a decorative outlook

* Used in mine sieving industries as sieving screen

Galvanized Welded Mesh Packing: moister-proof paper, PVC film, nude packed

Hebei Land Wire Mesh Prouducts Co.,Ltd.

Contact email: wiremesh at landwiremesh.com

Related Search

Galvanized Welded Wire Mesh

Galvanized Welded Mesh Panels

Electro Galvanized Welded Mesh

Galvanized Iron Welded Mesh

Welded Mesh

Galvanized Welded Wire

More>>